Client

Project Status

Location

In February 2024, Sensorem carried out a comprehensive asset inspection of the converter stacks at BHP Nickel West, utilising advanced drone technology and non-destructive testing (NDT) techniques.

What was the client’s ask?

The client needed drone NDT inspections for two steel stacks at its nickel processing site in the Goldfield to identify any new anomalies. As one of the most established Australian users of the ground-breaking Voliro-T flying robot, Sensorem was employed to thoroughly examine all externally visible surfaces of the stack, including guy wires.

We combined traditional drones with the latest in drone aerial NDT robotics to thoroughly examine the structure and identify any potential anomalies and ensure the ongoing integrity of the structure, showcasing our precision and expertise in industrial asset inspection.

Data Layers

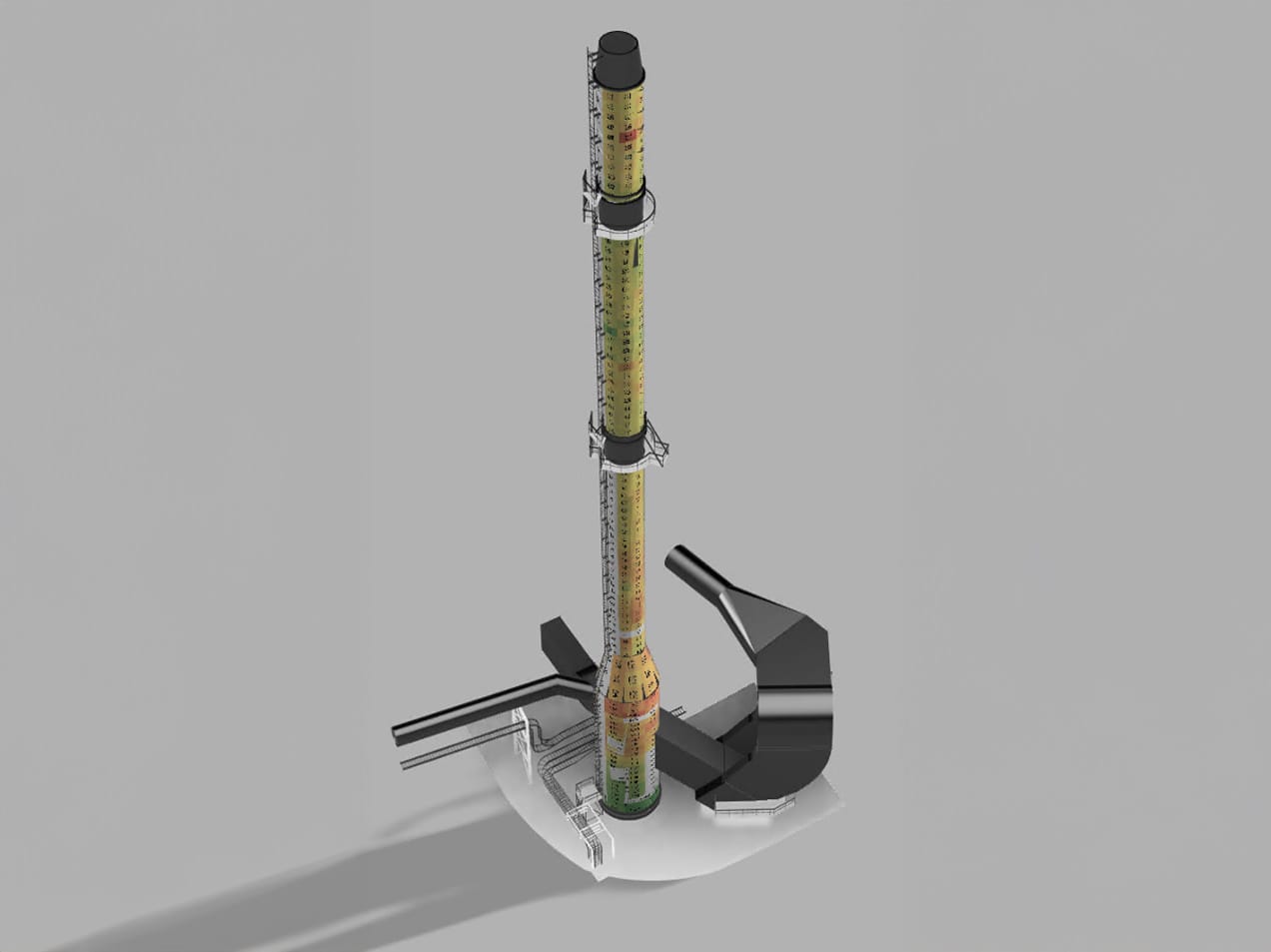

For this project, Sensorem’s data processing team leveraged the unique data captured on-site to create multiple layers of valuable information to provide the client with a comprehensive understanding of their assets.

Through a range of data capture techniques, we generated multiple layers of information about the asset. These layers work together to form a clearer and more detailed picture of the asset’s current condition, allowing for a better-informed decision-making process.

For this project, the team employed drone photogrammetry to create a detailed 3D model (BIM), which was then integrated with the non-destructive testing (NDT) data. This overlay of data layers provided enhanced context, offering a more comprehensive view than traditional inspection methods typically allow.

By combining these technologies, Sensorem offers clients a more robust and informed perspective on asset health and performance.

NDT drone technology

The Voliro T drone was key in overcoming the challenges posed by the hard-to-reach areas of the converter stack at BHP Nickel West, removing the need for traditional methods like cranes and scaffolding, which are often expensive, time-consuming, and potentially hazardous.

With its unique design, the Voliro T is fitted with a fully articulated robotic arm, allowing it to make direct contact with vertical and overhead surfaces. This enabled us to carry out comprehensive non-destructive testing (NDT) on the stack’s difficult-to-access areas, which would have otherwise required significant human intervention.

Project success

The drone’s ability to conduct NDT inspections, while providing real-time, high-resolution data greatly improved the efficiency of the inspection process. By reducing the need for scaffolding or heavy machinery, we also minimised operational disruptions, enhanced worker safety, and shortened project timeframes.

The precision and versatility of the Voliro T allowed us to detect surface anomalies and structural issues that could impact the stack’s integrity, ensuring a thorough and accurate assessment.

This use of the Voliro T drone highlights Sensorem’s commitment to using cutting-edge drone technology and innovative techniques to improve industrial asset inspections. By combining the latest in drone robotics with advanced NDT capabilities, Sensorem delivers more efficient, safer, and cost-effective solutions to meet the evolving needs of our clients and the industry.

Summary

Sensorem’s approach significantly improved inspection efficiency and enhanced worker safety by minimizing human exposure to hazardous environments. As well as being adept at utilising NDT drone inspection techniques for a wide range of asset inspections, we also employ LiDAR sensors, Drone-in-a-Box solutions, drone magnetometers and other sophisticated UAV technology to conduct our autonomous drone operations in remote and challenging operations across Australia.

Our capabilities also include creating detailed 3D models and digital twins, providing real-time data analysis, and supporting proactive maintenance strategies. Contact Sensorem today to learn how our drone-based solutions can revolutionise asset management across the mining, oil & gas, utilities, and telecommunications industries, ensuring safety, efficiency, and prolonged asset life.